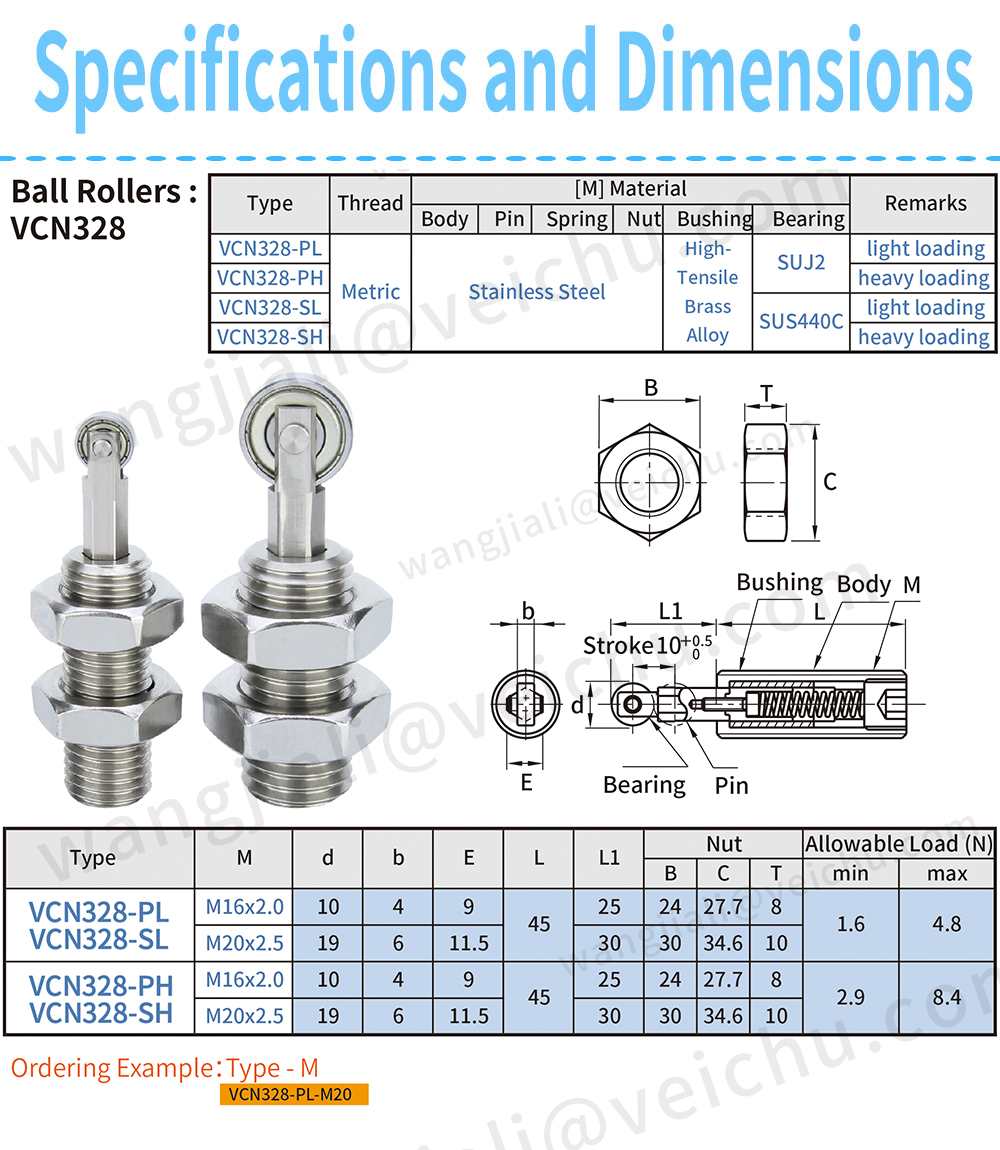

Material: Body、Pin、Spring、Nut-Stainless Steel; Bearing-Stainless iron

Surface: /

Size: M16*2.0 / M20*2.5

Sale modle: Wholesale

MOQ: 1pcs

Service: Provide customized services, including size, appearance, color, functionality, and brand development, etc

VCN328-SL/SH

VEICHU

| Thread Diameter: | |

|---|---|

| Availability: | |

| Quantity: | |

The Bearing Roller Spring Plunger is a precision mechanical component that integrates a rolling bearing, roller, and internal spring mechanism. It combines the precise positioning function of a spring plunger with the smooth rolling capability of a bearing roller. Its core design utilizes an internal spring to provide the roller with constant and controllable pressure, enabling the roller not only to bear loads and achieve smooth linear or rotational motion but also to automatically compensate for installation gaps and wear, while serving as a compliant driving or tracking element. It is widely used in automation, conveyor systems, and various precision machinery as a guiding, driving, clamping, and tracking component.

▲Compliant Tracking and Clamping:

The constant pressure from the spring ensures the roller maintains continuous contact with the surfaces of workpieces, cams, or guides of varying profiles, enabling shock-free tracking and reliable contact, thereby avoiding rigid impacts and jamming.

▲Smooth Rolling and Low Friction:

The built-in rolling bearing allows the roller to rotate with a very low coefficient of friction, making it particularly suitable for high-speed, continuous linear motion applications, effectively reducing power loss and surface wear.

▲Automatic Gap and Wear Compensation:

The spring mechanism automatically compensates for gaps caused by manufacturing tolerances, installation errors, or long-term wear, ensuring stable long-term equipment operation and reducing maintenance requirements.

▲Overload Protection:

When subjected to unexpected excessive impact or pressure, the spring plunger can retract elastically, absorbing energy and thus protecting the roller itself, the tracked workpiece, and the entire mechanical assembly from damage.

▲Versatile Drive Modes:

It can function as an idler roller, following surface movements, or as a drive roller, where external power drives the roller to traction or drive other components.

| Parameter Category | Specific Parameter | Description / Typical Range |

|---|---|---|

| Installation Dimensions | Thread Size | Metric: M16*2.0/M20*2.5 (can customize) |

| Roller Dimensions | Roller Diameter (D) | 10mm/19mm |

| Spring Performance | Spring Force | 1.6N-8.4N |

| Materials & Bearing | Material | SUJ2/Stainless iron |

1.Automation & Robotics:

Robot End Effectors: Used for compliant alignment and cushioning during part picking and placing.

Assembly Lines: Serve as guide rollers for smooth movement of fixtures or workpieces.

Cam Followers: Precisely track cam profiles to convert rotary motion into accurate linear motion.

2.Conveying & Transport Systems:

Belt/Chain Tensioning: Act as tensioners, using spring force to automatically adjust belt or chain tension.

Material Guiding: Guide web materials (e.g., paper, film) in packaging and printing machines to maintain correct path.

Sorting Mechanisms: Achieve smooth sorting and diverting of items via lateral pressure from the rollers.

●Summary

The Bearing Roller Spring Plunger is a highly integrated functional component that skillfully combines the elasticity of a spring, the smoothness of a bearing, and the load-bearing capacity of a roller. It provides a reliable compliant interface for modern mechanical design, significantly enhancing equipment adaptability, reliability, and service life while ensuring precise motion and effective force transmission.

We can design a special customized solution for you based on your actual usage scenarios. Welcome to consult.

We can design a special customized solution for you based on your actual usage scenarios. Welcome to consult.