Color for Handle: Blue

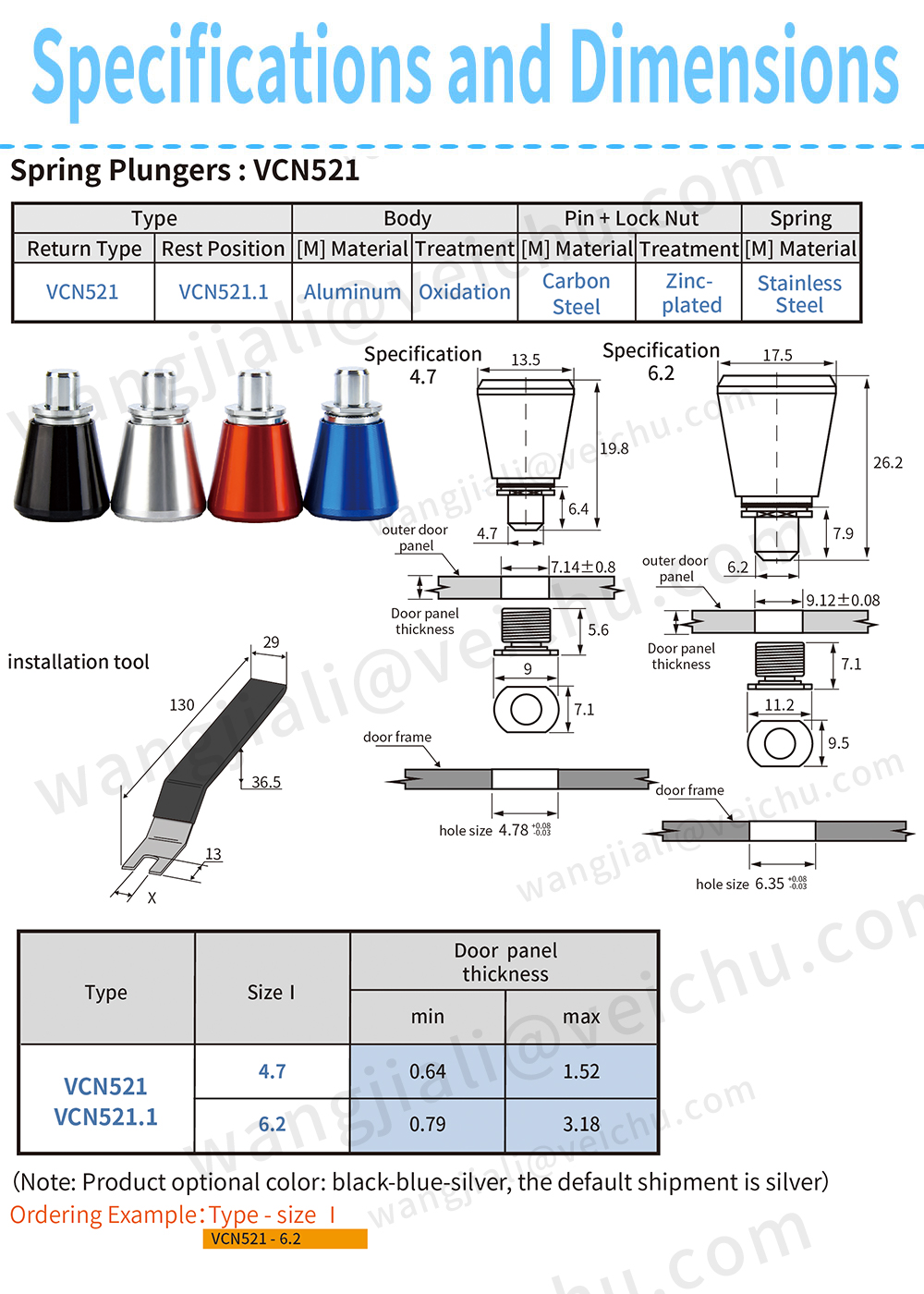

Material:Shell-Aluminum, Pin is made of Carbon Steel

Surface: /

Size of pin: 4.7mm/6.2mm

Sale modle: Wholesale

MOQ: 1pcs

Service: Provide customized services, including size, appearance, color, functionality, and brand development, etc

VCN521-Blue

VEICHU

| Diameter of Pin: | |

|---|---|

| Availability: | |

| Quantity: | |

●Product Introduction

Our conical head spring plunger represents an outstanding design, featuring an optimized combination of an aluminum alloy housing and high-carbon steel head pins. This configuration integrates the benefits of a lightweight structure, high strength and excellent corrosion resistance. It is an ideal component for achieving precise positioning, restriction and locking functions in modern precision machinery, automated equipment and lightweight structures. The unique conical die head design allows for smooth and precise engagement to the corresponding workpiece anti-seizing holes, providing stable and reliable mechanical performance.

●Structural Features

Exceptional Strength and Wear Resistance:

Exceptional Strength and Wear Resistance:

High-Carbon Steel Nose Pin: The core load-bearing and contact component is manufactured from high-carbon steel and undergoes heat treatment (quenching and tempering). This process ensures supreme hardness, tensile strength, and outstanding wear resistance, guaranteeing long-term accuracy and extended service life under frequent use.

Precise and Reliable Positioning & Locking:

Precise and Reliable Positioning & Locking:

Tapered Nose Design: The cone-shaped tip provides self-guiding and self-centering action, facilitating easy and accurate insertion into detent holes. It delivers a compliant locking force, effectively preventing part loosening due to vibration while minimizing wear on both the plunger and the mating part.

![]() Superior Lightweight Design:

Superior Lightweight Design:

○ Aluminum Alloy Housing: Significantly reduces overall weight compared to traditional all-steel constructions. This is critical for enhancing performance in weight-sensitive applications such as automated systems, robotic arms, aerospace, and racing components.

●Typical Applications

Automation & Robotics: For quick-change tooling, end-effectors, jigs, and fixture positioning on conveyor modules.

Precision Machinery: Used in fixtures, molds, and safety door locks on CNC machining centers and other equipment for secure locking and positioning.

Electronics & Semiconductor Equipment: Applied in wafer handling robots and inspection instruments where high cleanliness and precise alignment are paramount.

Automotive Industry: For jigs, fixtures, and gauges on production lines, as well as in lightweight locking mechanisms for high-performance vehicles.

Aerospace: Meets stringent requirements for low weight and high reliability in applications such as access panels, interior components, and equipment module locking.

Medical Equipment: Provides secure, quiet latching for adjustable parts on medical beds, imaging systems (CT, MRI), and other devices.

Furniture & Consumer Products: Used in high-end adjustable furniture and fitness equipment for discreet and durable positioning.

●In summary

This taper-nose spring plunger, with its aluminum housing and carbon steel pin, perfectly embodies the modern engineering principle of "weight reduction and performance enhancement." It maintains core strength and durability where it counts, while achieving significant weight savings and corrosion resistance, making it an intelligent choice for improving your product's competitiveness and reliability.