Color for Handle: /

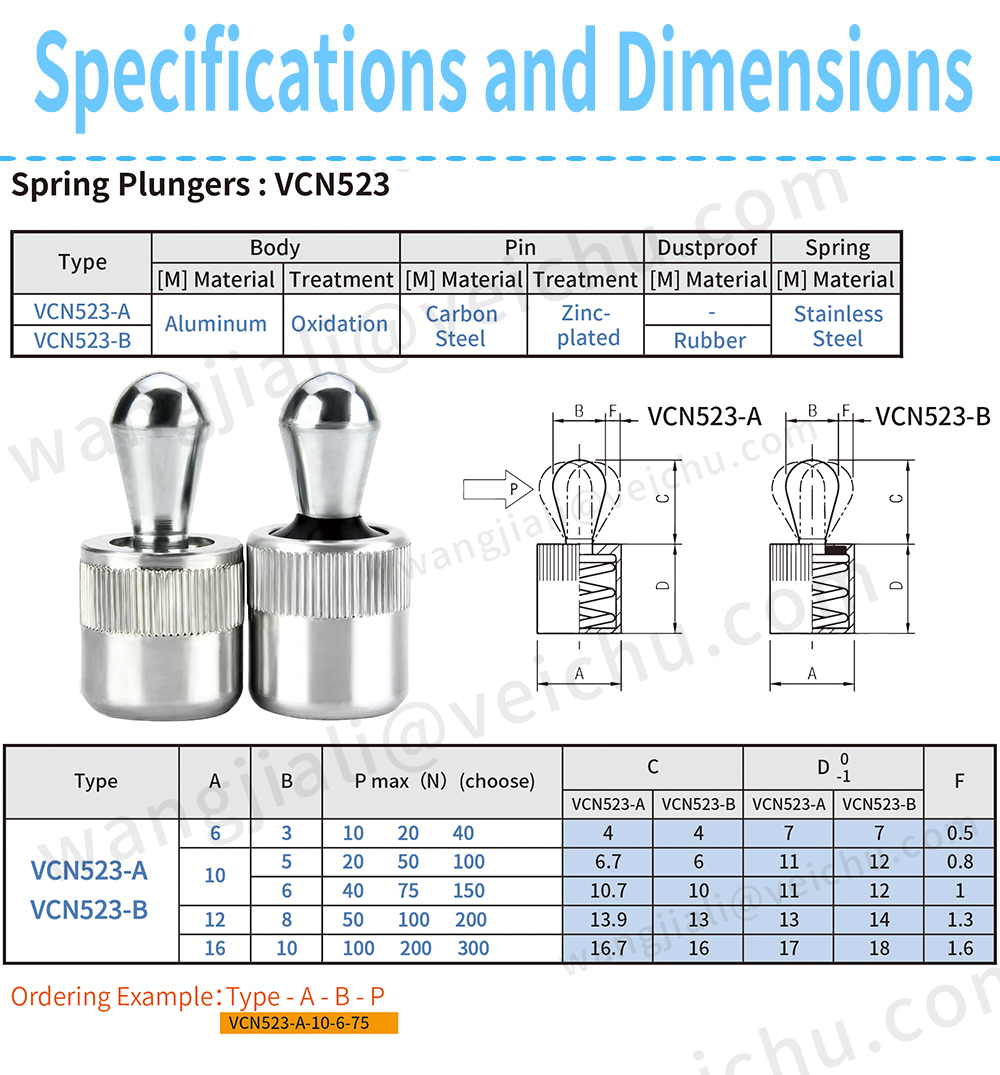

Material:Shell-Aluminum, Pin is made of Carbon Steel

Surface: /

Size of body: 6/10/12/16

Sale modle: Wholesale

MOQ: 1pcs

Service: Provide customized services, including size, appearance, color, functionality, and brand development, etc

VCN523-A

VEICHU

| Diameter of body: | |

|---|---|

| Availability: | |

| Quantity: | |

●Product Introduction

This is a side locating pin (model VCN523-A/B), featuring a composite material design of an aluminum alloy housing and a carbon steel pin: the housing is made of lightweight aluminum alloy, while the pin is constructed from high-strength carbon steel. It is an industrial fastener used for precise side positioning and quick locking of equipment components. The pin retracts and extends by pressing the top spherical handle, and completes positioning via the housing’s thread/slot structure, making it suitable for various side-fixing scenarios.

●Structural Features

●Composite Material Advantages: The aluminum alloy housing offers lightweight properties (reducing equipment load) and a refined surface finish, while the carbon steel pin provides high strength and excellent shear resistance—combining the dual benefits of "lightweight" and "durability".

●Precise Side Positioning: The pin has a highly accurate telescopic stroke and dimensional tolerance, enabling precise alignment of side positions between components to avoid offset or misalignment.

●Convenient Operation: Equipped with a top spherical handle and a knurled housing, the pin can be retracted/extended by pressing, allowing tool-free assembly and disassembly. It is ideal for scenarios requiring frequent adjustment and maintenance.

●Strong Adaptability: Two models (A/B) are available (differences in details adapt to various hole positions/mounting requirements), meeting the side positioning needs of diverse equipment.

●Typical Applications

●Automation Equipment: Side component positioning for assembly line jigs and fixtures, suitable for precise docking of robotic arms and testing equipment.

●Machine Tools/CNC Machining Centers: Side locking of worktable accessories and tool fixtures, ensuring stable component positions during machining.

●Instruments and Meters: Side fixing of modules in precision testing instruments, balancing lightweight design and positioning accuracy.

●Aerospace/Automotive Components: Side component positioning for lightweight equipment (e.g., drones, automotive interior tooling), adapting to "light load + high precision" requirements.