Color for Handle: /

Material:SUJ2

Surface: /

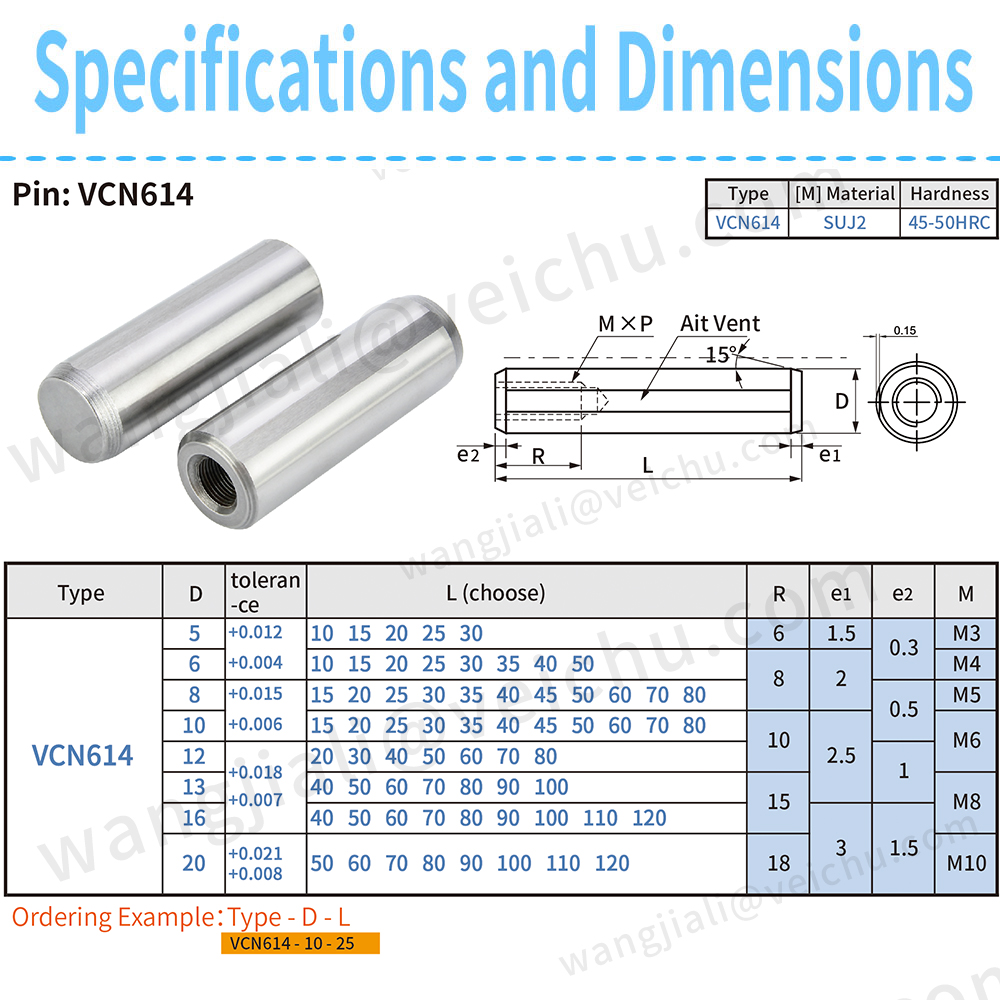

Size of body: 5/6/8/10/12/13/16/20

Sale modle: Wholesale

MOQ: 1pcs

Service: Provide customized services, including size, appearance, color, functionality, and brand development, etc

VCN614

VEICHU

| Diameter of Pin: | |

|---|---|

| Availability: | |

| Quantity: | |

●Product Introduction

The SUJ2 cylindrical dowel pin with internal thread is a core mechanical component engineered for high-load, high-precision, and high-rigidity applications. Its body is precision-machined from JIS-standard high-carbon chrome bearing steel SUJ2, undergoes special heat treatment, and features a precision internal thread at one end or throughout. This product combines exceptional hardness and wear resistance, outstanding fatigue strength, and convenient removability. It is ideally suited for demanding applications involving heavy loads, impact, and requiring precise positioning with repeated assembly/disassembly, making it a critical locating and connecting component in high-end molds, precision equipment, and heavy-duty machinery.

●Structural Features

1.High-Strength Limiting & Stopping: Its core function is to withstand high radial and axial loads, precisely restricting the movement of associated components and preventing displacement in high-vibration or shock environments.

2.Convenient Installation & Removal: The internal thread design allows for easy extraction or precise pressing using a pin extractor or a bolt, greatly simplifying installation and maintenance procedures in confined spaces or for interference fits.

3.Precision Location: Serves as a high-precision locating pin, ensuring repeatable positioning accuracy for mold clamping, heavy-duty fixtures, or precision equipment components.

4.Load Transmission: Effectively transmits shear forces and a degree of torque, functioning as a high-strength connecting pin.

5.Extended Mold/Equipment Life: Its superior wear resistance reduces accuracy loss caused by wear on locating parts, thereby extending the overall service life of molds or equipment.

●Typical Applications

▲Stamping Dies & Plastic Molds: Used as guide pins, locating pins, and stop pins, withstanding immense impact and friction during high-speed stamping or precision injection molding to ensure clamping accuracy and mold life.

▲Die-Casting Molds: Employed for precise location and stopping of core inserts, sliders, and other critical moving components, enduring harsh high-temperature, high-pressure environments.

▲Jigs, Fixtures & Automation Equipment: Acts as a core locating element in heavy-duty welding fixtures, large machining center fixtures, and automated assembly lines, ensuring production stability and repeatable accuracy.

▲Construction Machinery & Heavy-Duty Vehicles: Used for connection and positioning in transmissions, chassis, or working devices, bearing heavy loads and vibration.

▲Precision Machine Tools & Spindles: Used in machine tool spindle heads, tool changers, and other areas requiring high-rigidity positioning.

▲Gearboxes & Drive Systems: Serves as a bearing locating pin or a retainer ring pin, ensuring stable positioning of transmission components.

▲Maintenance & Retrofitting: Functions as a standard spare part to replace worn-out standard dowel pins in existing equipment, quickly restoring accuracy and performance.